The Future of Emergency Cardiac Care

concept

LifeLine is a revolutionary automated CPR system designed for Laerdal Medical that integrates defibrillation electrodes directly into the compression piston. This innovation enables double sequential external defibrillation (DSED) for the first time in pre-hospital care, significantly improving survival rates in refractory cardiac arrest.

info

Umeå Institute of Design

Laerdal Medical

Pierre Brand

Nicolò Vincenzi

2025

10 weeks

The Challenge

Research and Development

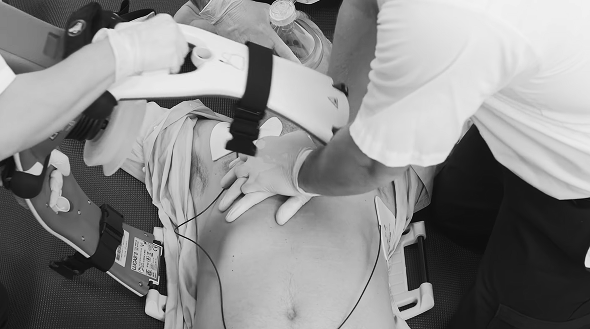

We worked in collaboration with Laerdal Medical, a Norwegian company that is a global leader in resuscitation devices and training. Throughout the research phase, we conducted extensive field work and training sessions with paramedics in Umeå, Sweden to understand real-world workflows and challenges.

Extreme scenario training revealed how stress, noise, darkness, and obstacles impact CPR performance.

The Opportunity

Double sequential defibrillation improves survival

The DOSE-VF trial showed that delivering two shocks in sequence significantly improves outcomes for patients with refractory cardiac arrest.

But no product existed to make this possible in pre-hospital care.

DSED uses an additional pair of pads to deliver a sequential shock, significantly increasing the likelihood of reaching the heart

higher survival withDSED vs standard in

heart rhythm

Source: DOSE VF Trial (2022)

Annual deaths in America

Survival rate (OHCA)

Survival loss per minute

Why it doesn't exist yet

Current technology creates barriers

Paramedics deliver 21% of first shocks — yet current technology prevents them from delivering the most effective treatment.

"We are aware of the latest DSED evidence, but accessing the back and chest with current equipment is practically impossible without critical delays that compromise the patient's outcome."

— Paramedic Umeå, Sweden

Sternum blocked

Compression machines obstruct electrode access

Patient repositioning

Accessing the back interrupts compressions

Cable complexity

Multiple devices create entanglement

Unifying DSED and automated compression machine

This unification streamlines resuscitation by consolidating components, enhancing portability, and accelerating deployment. By organizing cable management, LifeLine eliminates environmental clutter for the paramedic.

Crucially, the system facilitates immediate access to the patient's back for posterior pad placement without interrupting care. With its unique wrap-around arm design, LifeLine transitions from manual to automated compression in under 3 seconds maintaining the continuous blood flow essential for shock success.

Compression Machine

Robust, lightweight, and precisely controlled

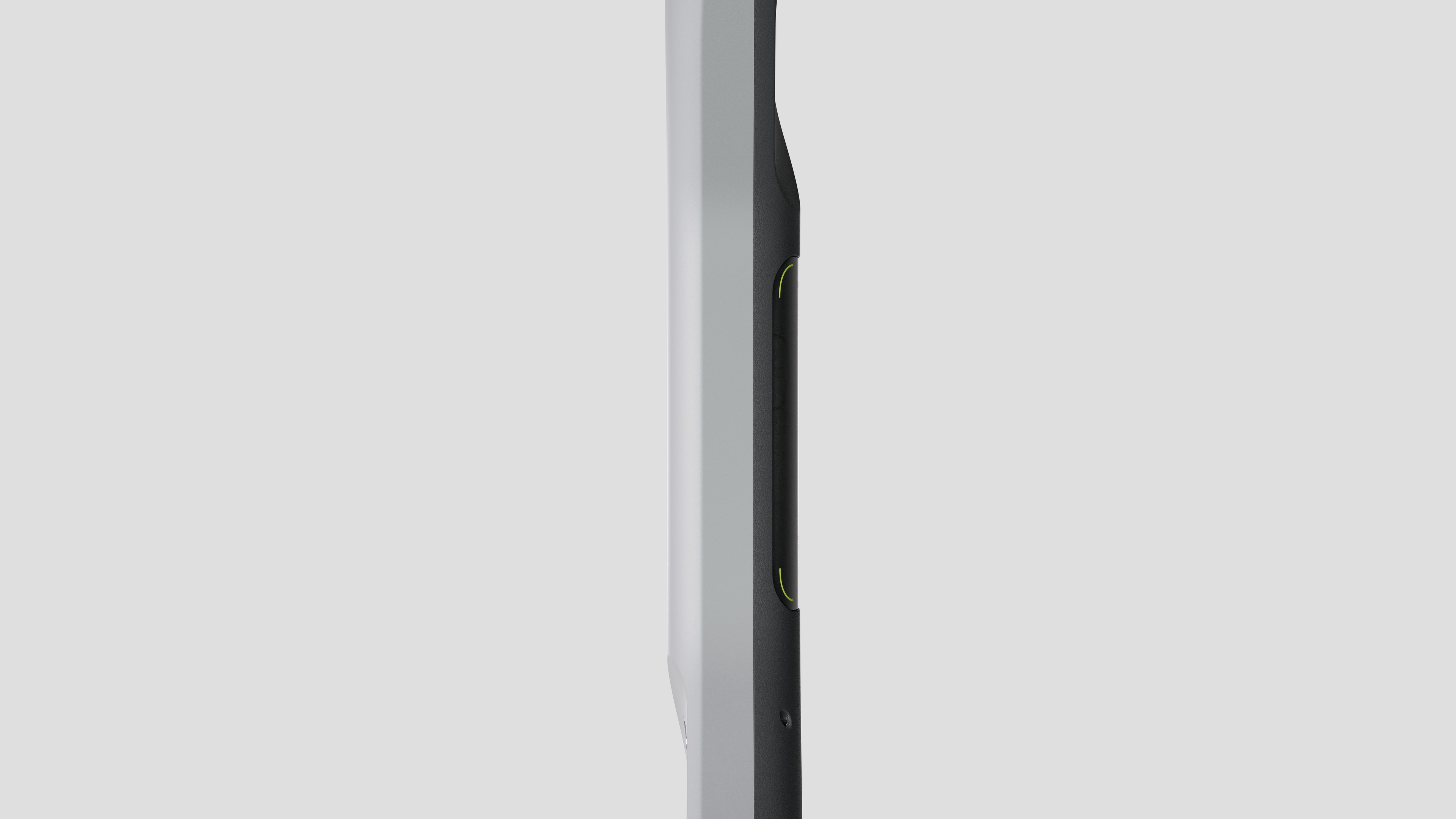

The compression arms are controlled and unlocked via two sliders on each arm, ensuring secure positioning and safe operation. The construction balances robust performance with lightweight portability.

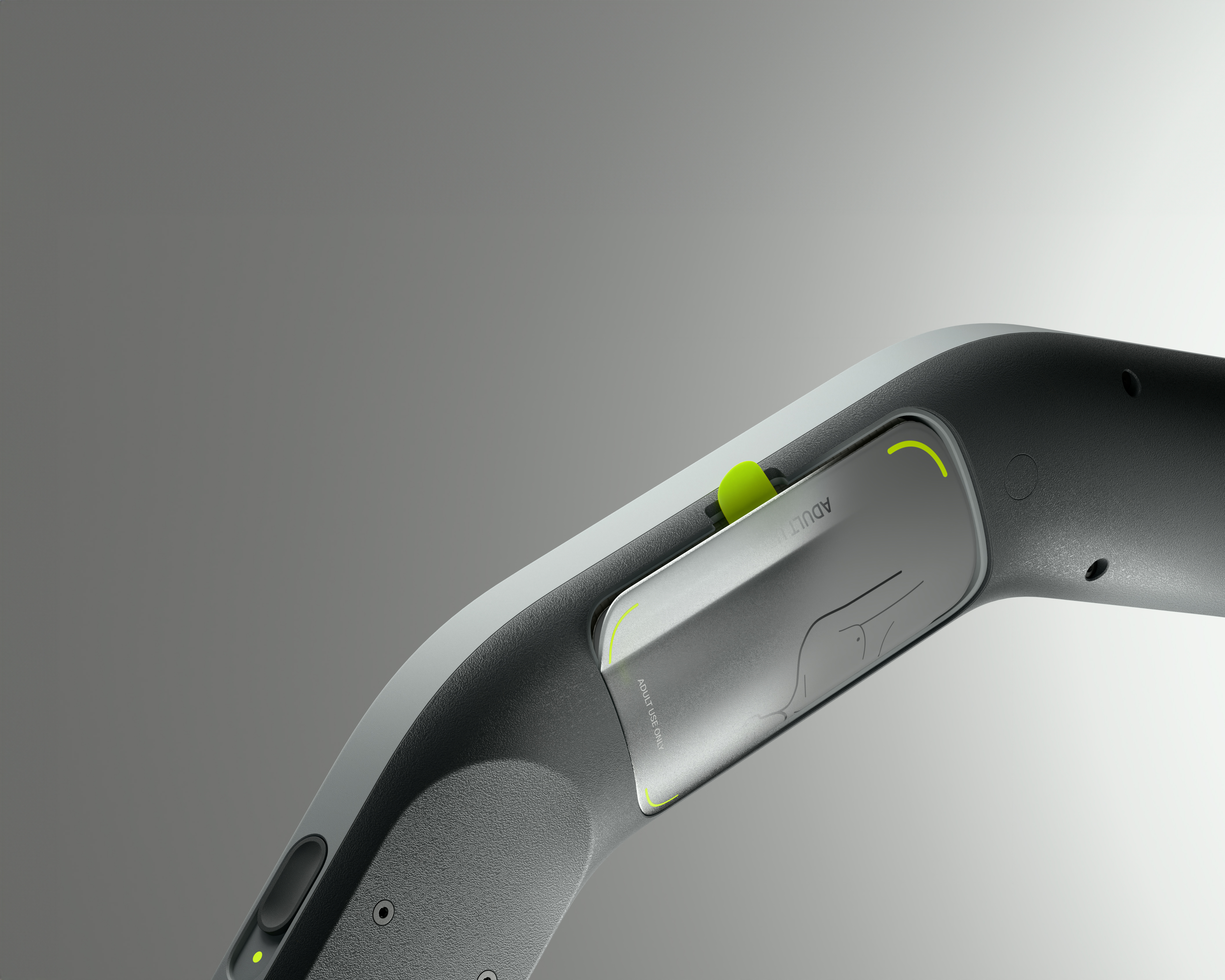

Integrated Pad System

Defibrillation pads ready for instant deployment

The electrode pads are folded and stored in custom-designed canisters integrated into the arms and back of the device. This makes them ready for deployment in seconds—and replacing used pads is equally effortless.

Defibrillator

Synchronized for double sequential defibrillation

The defibrillator connects with the compression machine to optimize the resuscitation process. It's the first defibrillator designed specifically to enable double sequential defibrillation in pre-hospital settings—coordinating dual shocks through both the integrated electrode and traditional pads.

Prototype Development

Prototype and Testing

Early-stage testing of the compression machine prototype validated with paramedics and healthcare professionals in Umeå, Sweden to refine the design and ensure optimal performance.

Materials & Finishes

Designed for durability and hygiene

Every surface is optimized for rapid cleaning between uses. High-visibility lime accents aid quick identification of controls and pull tabs in high-stress situations.